The world of nanosatellites is at a juxtaposition, in that nanosats have seen tremendous growth in capabilities and at the same time their dimensions are shrinking still further. Though miniaturisation of electronics and satellite systems has enabled a wave of NewSpace activity in the past decade, current methods are plateauing. What approach will be used for the next generation of satellite systems? Our ESA BIC incubatee Spherical Systems is using emerging techniques in the semiconductor industry to design systems at the microchip level to deliver optimised satellite systems powered by silicon.

Thomas Parry, Spherical’s founder, joined as an entrepreneur in the ESA BIC programme in September 2022 and is busy fine-tuning plans for the satellite-on-a-chip core technology and product development. We chatted to Thomas to find out more about his space related business.

What is your background?

I come from a nanosatellites world – I was there at the start and saw this area take off during my time in Glasgow designing satellite systems for Clyde Space, when the company was relatively new. Over the course of working there, I got to collaborate with startups and other companies in the field, including Spire. What we were basically trying to do was make the most powerful and reliable systems in as small a space as possible. The smaller the satellite, the smaller the costs – not only the launch costs but costs in general.

Care to share a quick timeline of the launch of nanosats?

Looking at the history, what people call “old space” or “traditional space” and what existed before the year 2000, the satellites were big – some of them were like the size of school buses – and costly. The problem was there was a vicious cycle: they were expensive, so no one wanted anything to go wrong; so then you’d have to do a lot of engineering to basically reduce the risk to as low as possible, which then means it costs a lot of money – and round you go again.

Then, there was a change in the space industry of how things were done, partly due to miniaturised satellites – CubeSats at 10 x 10 x 10 cm size – which were invented by Professor Bob Twiggs and colleagues (read more here). These are standardised satellites that can be stacked with a standard interface on the rockets to slot them in. This was essentially an academic/student project that wasn’t initially taken seriously. Around the time I started my professional career, companies were just starting to use them. That is how these nanosatellites launched into the NewSpace market.

What was it that sparked you to start Spherical?

I wanted to look for a new way to make nanosats small and powerful. When I moved to the Netherlands in 2018, I switched industries to semiconductor design (working for SystematIC Design) – so rather than combining chips and components on a circuit board, I was actually designing just the chip components themselves and spent 4 years designing microchips for different companies, including some startups.

I had always wanted to start a company, so I eventually put the two aspects together to use the semiconductor design techniques that I had learned and go and solve the problems that had been encountered previously. The goal is to apply this semiconductor route to the space industry.

Is this technology new for space applications?

Yes, it is unique for the space industry. It does already exist in, for instance, the iPhone – to really make the best systems, you need to design your semiconductors to deliver the system performance. The highest performing chip is required for complex, portable electronic systems (a mobile phone in that case). We are applying this model to a satellite industry – for satellites that are small, high performance, reliable. The goal is for Spherical to design the highest quality and highest performing satellite systems available – at the semiconductor level. The path to optimal performance lies in our satellite-on-a-chip technology.

But silicon-based custom chip design is still quite expensive, and this is where I see the parallel work described earlier in the space industry with the vicious cycle. It looks to me that chip design is about to have the same change that NewSpace had of breaking that cycle and that’s really fuelled by a lot of things that’s going on now with the open-source chip design. We’re using these fledging capabilities to dramatically accelerate satellite system performance – towards a real ChipSat reality.

Can you tell us about your approach to satellite systems?

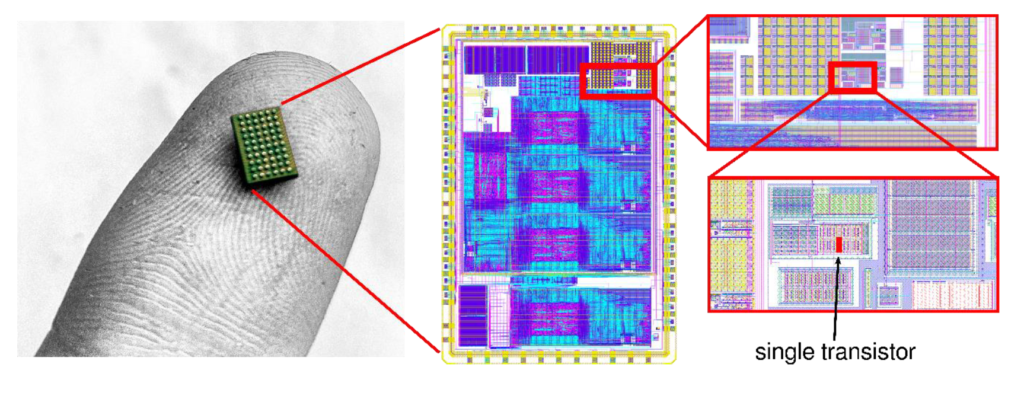

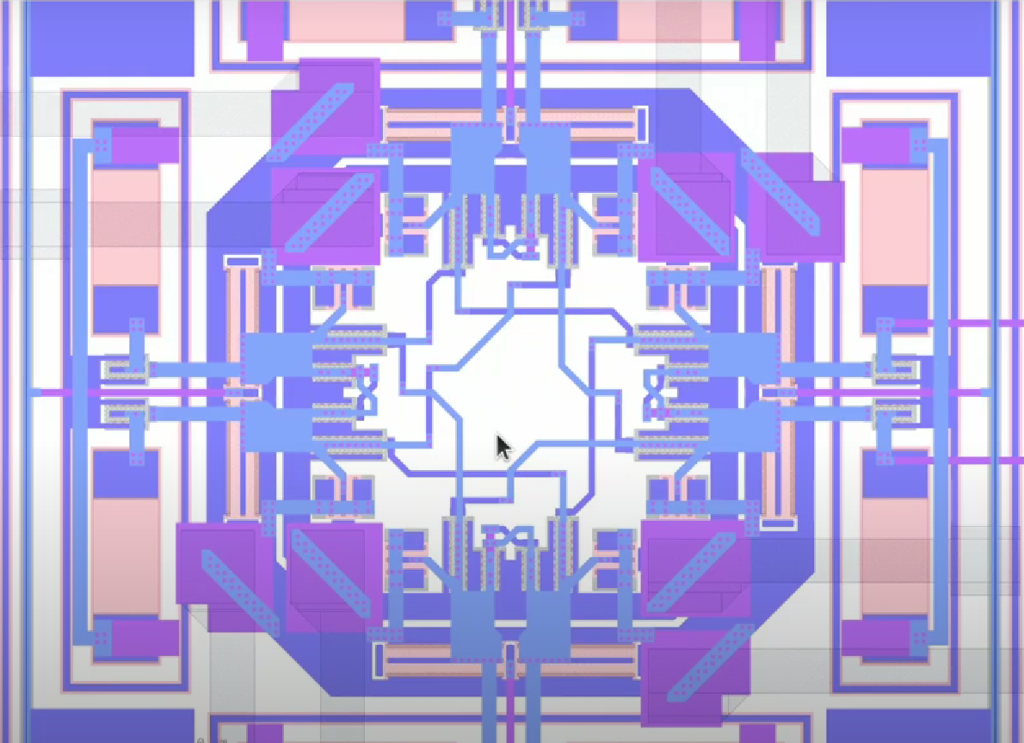

The current industry standard utilises a design by controlling how microchips are combined, whereas our design process involves manipulating the individual transistors. We are using these advancements in productivity and agility in semiconductor design to create the next generation space systems. The visual (see top image) of a microchip, that I designed and manufactured using open-source silicon, gives an idea of the size of a single transistor (≈ 180 nm). Manipulating electronic circuits at the individual transistor level provides orders of magnitude more control over the performance of the final product – enabling things that cannot be achieved otherwise.We are integrating most of a nanosatellite core avionics into a single chip. This chip is designed from the ground up with the satellite performance in mind. Our technology starts from the lowest abstraction layers – drawing doping profiles in silicon, working through all layers of the design up to the final core avionics system. Spherical will offer a drop-in bus system which is a quarter of the size of current market offerings while being many times more reliable.

Has being involved in the open-source silicon movement helped?

I was involved when the open-source semiconductor community began in 2020, following a Google-funded initiative – and it was here the building blocks of my company began to form. This demonstrated to me that there was the possibility to make custom chips for smaller volumes much more effectively than was possible before. Now, custom chip design is rapidly changing as agile-semiconductor practices emerge driven by open-source efforts. This is bringing software best practices to semiconductor design to drastically increase productivity. The rapidly growing space market provides the perfect canvas to deploy emerging capabilities in agile semiconductor development.

What are you working on right now?

The company has been formed to exploit the window of opportunity in market and technological trends that make this the perfect time to bring our technology and product to the market. The plan is to develop the core technology and product – but the hardest thing at the start is deciding what the first product will be and the best place to focus initially. So when I first started, I was looking at creating the entire nano-avionics system, incorporating all the parts that the nanosatellite needs – including all basic computation, power and communication. But for now, I’m starting with a smaller subset – i.e. the power conditioning and distribution unit (PCDU) – and focusing on delivering that product first.

Initially, I am doing market research and sending out the product brief. I like to put in some hooks and really see what people respond to. Basically, we want to outline that our solution provides unbeatable technical performance in size, weight, reliability and software control but the true value to our customer lies in the fact they can forget about all the “boring” parts of the satellite.

What do you look forward to during the ESA BIC programme?

I definitely intend to leverage the ESA support, particularly on the technical experts side, as this gives access that money can’t buy. And the coach matching available to incubatees is great. I am really looking forward to working with the coaches. As my product takes shape, then the business side and advice will be vital. Because I come from a very technical background, I am trying not to just throw myself into the technical aspects. I need to make sure that the business and the product makes sense before diving in because I think it’s too easy just to focus on the fun part essentially.

I hope to really focus more on the market analysis with the coach. The thing about the space industry is the unit economics are quite unique, in the sense that it’s low volume, high value, which means that it’s non-linear. In terms of a viable business, the difference between no business and a good business is actually quite a small number of units sold. So, you must be sure you are focusing on the right thing before launching into it.

Any advice for startups who wish to apply to the ESA BIC?

Things will change more – and quicker – than you think they will; I thought I had a full plan and now I realise there’s a better way to the plan! It’s always going to evolve; it’s not going to be one thing that you just execute. It’s very hard to know the barriers or the constraints before you do it. Occasionally, you might have to repivot on some items – but that’s part of the learning process; finding out what’s possible, what’s not possible and where the opportunities are.

What was your route to ESA BIC?

I found out about the ESA BIC programme and the application deadline though the SBIC coach Johan Leijtens (LENS R&D), who I had done work with and who was himself an ESA BIC alumnus, and I also had contact with an earlier incubatee Kartik Kumar (satsearch). It helped that I took part in the Ignition Programme offered by SBIC to prepare startups for incubation, and then I applied to the next round of ESA BIC. I’m not sure if it was expected that I go straight ahead, but I wanted to take action and didn’t see the point of waiting around.

So, any budding space business entrepreneurs who are reading this, listen up! We have our next ESA BIC deadline approaching, so now is the time to start preparing your application documents. We recommend joining the series of webinars to get more information: details here.

ABOUT SPHERICAL

Thomas Parry, founder of Spherical Systems, works on creating next-generation satellite systems powered by semiconductor innovation. He is a world leader in the open-source semiconductor community where he created the world’s first open-source satellite radio transceiver microchip project. Thomas makes key contributions to the community’s technical ecosystem, has represented the community at Institute of Electrical and Electronics Engineers (IEEE) events and provides guidance on technical and community direction. The company is currently incubated at ESA BIC Noordwijk. spherical-systems.com

Prepare your space business idea for lift-off!

Don’t miss out on the support that can lift off your space business. Take action in 2023. Get ready for the ESA BIC spring application round by discussing your idea with our team, joining the Q&A webinars and preparing your business plan.