Offshore wind turbines are a steady source of renewable energy. Due to heavy weather conditions at open sea, inspection is necessary a lot. Ironically, the way this happens now is not sustainable at all. A ship is needed to bring a person or drone there, which means high emissions and high costs. Shore Systems is solving this problem by building a drone that is able to inspect those far away offshore installations – from land.

Shore is a space related startup currently incubated at the Dutch business programme from the European Space Agency, called ESA BIC Noordwijk. It was founded by 4 young entrepreneurs with a background at TU Delft – Ralph Krook, Thom van den Homberg, Frederik Hogenbosch and Victor Sonneveld. Here, they will foster space technologies for applications on earth. We talked to co-founder Victor about their hydrogen powered drone.

How does your system work exactly?

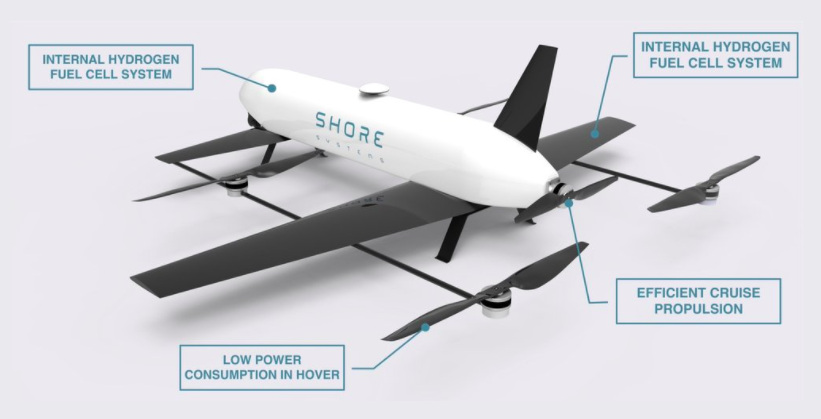

Our drone can hover for very long times to do inspections. Next to that it has a large action radius. Current drones have one or another as their unique selling point. The unique thing about our drone is that it has the best of both worlds: a healthy balance between hover endurance and range.

A hydrogen tank and fuel cell are integrated in our drone, replacing a battery. In our case hydrogen makes sense because it has a high energy concentration. Anything that flies needs to be light and hydrogen is a good carrier of energy. Each fuel cell still has an electrical drivetrain, so we still can make use of the propellers. This makes our system so stable.

In terms of controlling the drone, a pilot controls it while on land, using a video link, obviously beyond visual line of sight.

What can you tell us about the space technology you use?

We integrated several systems and some of them are supplied by the space industry. We use GNSS to define our position, and use satellite communication as a backup for the direct radio link between our drone and the ground station.

How did the idea for Shore came to be?

Well, all of us have been students at the Delft University of Technology (TU Delft). In 2018, then as students, we came across the GoFly competition from Boeing. The assignment was to create a one-passenger drone. We created a team of 20 people and we called our team Silverwing. Eventually we got in the top 5, out of 200 ideas entering the competition. We didn’t win unfortunately, but we’ve learned a lot during that time. We wanted to explore the world of drones a bit more. So from the Silverwing core team, we eventually founded Shore.

From a passenger drone to inspection drones is a big step. Because the drone market is pretty saturated, we looked to common applications of drones and tried to identify gaps in the market. We found out it’s not necessarily cargo or transport that’s done by drones, but inspections. And we found that the way offshore inspections are done is particularly cumbersome.

What’s the biggest challenge in the (inspection) drone industry?

In terms of inspection, each operator has slightly different demands. So basically an inspection drone needs to be useful for the large majority, say 95 percent, of potential customers. This also is true for the general drone industry – you have to be allround good while being unique at the same time.

What’s the status of your development? (January 2022)

We have a prototype, a scale model of our solution. It already has flown inside. Right now we are fully focused on developing the fully-sized drone, and within the next six months we will test it with a partner operator. At the end of 2022 the system must be operable for them to use with their clients.

What are Shore’s long-term plans?

We want to make our product better every year, but now our strategy is to quickly enter the market with a first version. While it’s on the market, we’ll add features and upscale our production to eventually have a solid production line.

Do you have a certain milestone to share with us?

We are proud to work with our partner, the operator. This collaboration was partly subsidised by RIMA, an European network of entities in the maintenance and inspection industry.

You all chose to enter the ESA BIC Noordwijk programme, why was that?

As former TU Delft students we have a strong technical knowledge. But running a business is something else compared to participating in a student team. So we looked for an organization that could help us with the business side of things. So that’s how we came across ESA BIC Noordwijk. We entered the Ignition Programme to prepare us for the incubation trajectory. That programme really helped us to validate our business and we learned how to communicate better about it for the application – and in general as well.

How would you describe your team synergy?

It’s important to do other things together next to work. For instance, Thom and I practice jiu jitsu together. In general we know each other very well. When we did the GoFly competition, we rented a house that was practically too small for all of us so we got to know each other on a really different level. In the end that helps in operating the business.

What’s your business’ secret ingredient?

Can I say caffeine? Next to that, you’ll have to believe in something and persevere at all times. We think perseverance is really important because setbacks will happen. I think a lot of startups can recognise themselves in this.

Interested in becoming a space related business? The ESA BIC Noordwijk programme helps aspiring entrepreneurs with creating their prototype or market introduction with their solution. More info: