Revolv Space, a startup currently incubated at ESA BIC Noordwijk, is improving the performance of small satellite buses to enable continuous operations of their payloads. The target is the next generation of small satellite constellations. The engineers of the Revolv Space team do that by designing, manufacturing, assembling, and testing plug-and-play devices that increase the performance of small satellite buses. The team has developed the only solar array drive assembly on the market that is as reliable as fixed solar panels. In this interview, we get insights into the company’s plan to address the current limitations of small satellite buses and shine a light on its first product: SARA, the Solar Array Rotary Actuator.

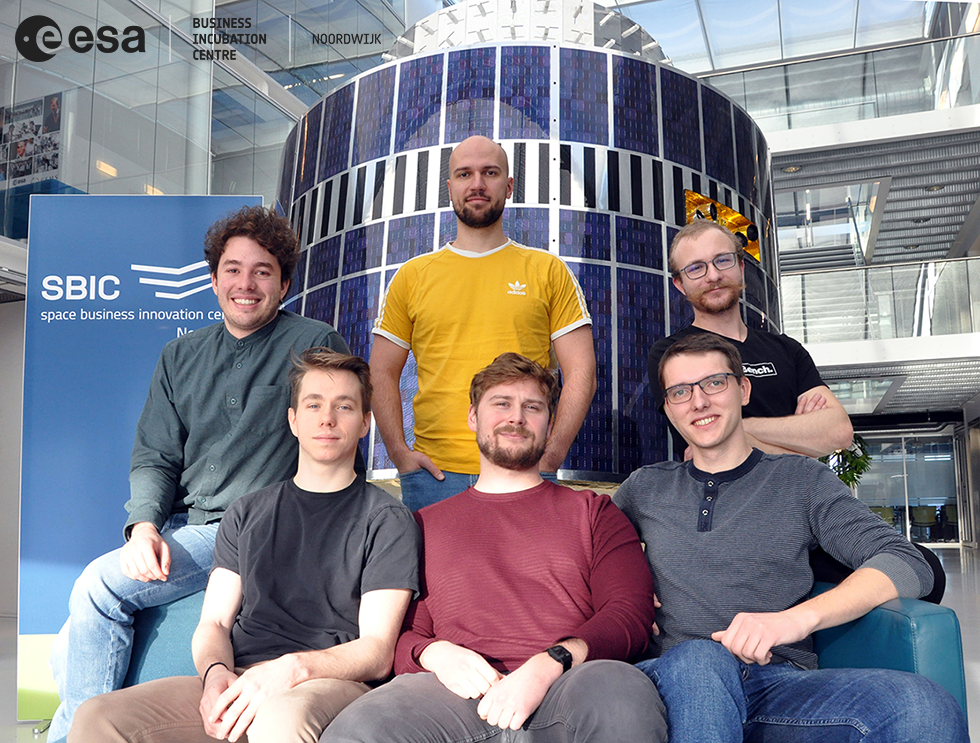

Through this flagship product, Revolv is hoping to remove the taboo status of using mechanisms in small satellites. The team is hard at work to prove that it’s possible to create a reliable and cost-effective subsystem that can improve the performance of even the smallest satellites. The startup was founded in 2022 by the four founders: Marco Sala (CEO), Michal Grendysz (CTO), Filippo Oggionni (CCO) and Aleksander Fiuk (software engineer). Since joining the Dutch business incubation programme of the European Space Agency at ESA BIC Noordwijk in October 2022, Revolv’s team has been expanding – currently totalling six people and with ongoing recruitment for a new embedded systems engineer. We chatted with Filippo to find out how Revolv is giving satellites superpowers.

How did Revolv come about?

We started the SARA project in 2021, thanks to a startup voucher handed out by the Aerospace Innovation Hub, when we were all aerospace engineering students at TU Delft on the Space Flight track. It began as a side project; around that time, we participated in the TU Delft Impact Contest and some pre-incubation programmes (such as SBIC’s Ignition Programme, Primo Space’s Quasar and PLNT Leiden’s Venture Academy). That’s really when we thought, “OK we’re learning a lot of stuff and this seems promising, we really should give it a shot.” These programmes helped us adopt a more commercial angle, going to conferences to speak with potential users and looking for funds – both private investments and grants. Then, in early 2022, it really took off: we registered our company, gained commitment for some funding and got selected for ESA BIC. Until then, the team was pretty much scattered around. Some people were in Delft, some were in their home countries (Italy and Poland), with some of us working full-time and others focusing on their thesis. After some time working on Revolv on the side, it was becoming too difficult and we wanted to give it our real focus and full commitment.

What steps did you take next?

In September 2022, the four founders started working full-time and shortly after we hired Krzysztof and Slawomir, two engineers that gave us a great boost in the technology development. In the second half of 2022, the business team, composed by Marco and myself, was in Italy to attend the Takeoff Accelerator programme in Turin, through which we gained the support of our first investor, Italy-based institutional investor Cassa Depositi e Prestiti. This programme and its mentors gave us the right tools to validate the problem small satellite operators face and the features of SARA, our solution to such problem. Since January 2023, the full team has been based out of ESA BIC Noordwijk. We enjoy working together in the same office. It is more motivating and fun, and it is great for the team dynamics and morale.

What is the story behind Revolv’s identity?

We chose the name as it links with the fact that we’re dealing with satellites revolving around the Earth. Revolution is quite a recurring movement in space; moreover, our flagship product is an actuator that revolves around its axis. We wanted to have this theme in our name and also in our brand identity. The mission of Revolv is to make payloads on satellites operate for as much time as possible. Therefore, we wanted our logo to reflect the continuity of payload operations that we are working towards with our solutions.

Can you share details of your rotating flagship product?

Revolv’s flagship product is the Solar Array Rotary Actuator – or SARA for short. We also refer to it as the space sunflower, as SARA intuitively mimics the behaviour of a sunflower and it does it autonomously. SARA is a solar array drive assembly that rotates solar panels around one axis and offers an automated tracking mode to enhance power generation on board the satellite. The autonomous tracking feature is possible thanks to the embedded electronics and sensors that we developed. SARA is also equipped with a patent-pending backup mechanism to restore a default orientation of the panels if required, so it is fault-tolerant by design – a different and innovative approach to reliability that has been validated with satellite integrators. This backup mechanism has received appreciation by potential customers, as SARA is the only product on the market with such a high level of reliability.

How do you plan to address the power limitations of satellite buses?

On a high level, satellites are composed of two main functional systems: the payload and the bus. The payload is what generates data, so essentially the money maker for the company, while the satellite bus (i.e. the main body and structural component of a satellite) makes sure that the payload survives and operates properly and supplies all the resources to the payload, such as power, data management, thermal control, etc. The problem that we saw in small satellites used for commercial purposes is that, even though the performance levels and requirements of payloads are increasing, the capabilities of the satellite bus have not seen similar improvements over time.You have cutting edge payload technology in terms of sensors and antennas for the payload, so we believe that the satellite bus could improve more to provide the resources required by advanced payloads.

At the moment, the stagnation in the development of bus performance is actually keeping payloads from generating as much data as they could. So, you end up sending a satellite with a camera that does not operate at full capacity – usually between five and ten percent of the time spent in orbit. This can be due to multiple reasons: not enough power available on board to operate continuously without pointing the entire satellite to the sun to recharge the batteries; the satellite gets too hot and then you have to stop your camera operations; or you have to make a change to your orbit and then, again, you have to stop the camera from taking pictures. So, our mission is to really make sure that the camera – or whatever other payload – can always operate. A logical solution to the power limitation is to rotate the solar panels, providing a more efficient way to generate power. No matter what you do on the satellite bus, you should be able to do it while you operate your payload. We always want to give priority to the payload, because that’s what matters for commercial satellite operators.

What is your approach as you go-to-market?

We qualify as a satellite component manufacturer. We focus on the components that really make a difference for the satellite, so those components that are more advanced and more complicated to develop for a satellite integrator. Satellite integrators go through make-or-buy trade-offs; we focus on the products that the satellite integrators prefer to buy rather than make in-house themselves. This happens because of the money, expertise and time required to develop such components. We believe satellite integrators should focus on the system level; interacting with their own customers is already a tough job, so we want to relieve them from further technical developments of small, specific and critical parts of the satellites. To do so, we need to deliver components that are reliable but also easy to integrate and operate. For now, our solar array product (SARA) is our main focus. The medium-term goal is to expand the offering of SARA by adding solar panels, the Hold Down and Release Mechanism, and the Electrical Power System embedded in SARA. In the long term, we also want to start other projects to solve different limitations of the satellite bus, such as data downlink capacity and thermal management, while also adopting a more industrial and less custom approach to the manufacturing, assembly and testing of our components.

Being a component supplier is a good position for us as there are many constellations being funded, which will need reliable and high-performance components like SARA. Integrators will need products delivered in high volumes with low lead times. We are already taking steps in that direction by optimising SARA for fast production and integration. Focusing on the current version of SARA for the next 6–9 months will allow us to get to space, prove that the technology works and establish ourselves as a reliable component supplier. Once we get there, we can expand and progress on those other projects further. Despite our young age, the combined level of experience in our team is remarkable; nevertheless, we don’t have the 20 years of experience that some other people have when they found space companies. So, for us, it is paramount to prove that we are reliable with the first product and then move on, instead of being too broad from the outset.

What stage is your solar array product SARA at now?

Right now, we are at Technology Readiness Level 5. This week, we are having a Critical Design Review with experts from ESA, NASA, ASI, from academia and from industry. The development of SARA is covered up to the in-orbit demonstration, including all the design, assembly, manufacturing and testing on the ground. We now have an engineering model that has been proven to work in the lab. We are in the process of procuring the components to assemble the qualification model, which will then undergo a thorough testing campaign (including functional and environmental tests) that we will run in the next few months. We are working closely with users to make sure that the offering of SARA and its performance are aligned with their requirements. The goal is to have a flight model ready by Q4 2023 and launch it somewhere in 2024 – that’s our target.

What’s your main challenges to prepare for launch?

One is surely the range of expertise required. SARA is only one subsystem, so it may seem that it is not so difficult to develop, but SARA is actually a complete subsystem. It includes sun sensors, electronics and control logic (all health monitoring, processing of the sensors’ signal and required computation), and the actuation – so the mechanism and a motor. It’s an end-to-end system, so it is not trivial. You need different expertise to develop such a subsystem: mechanical engineers to design; structural engineers to make sure that the product survives the launch loads; and electronics engineers capable of designing the electronic board, selecting the right components and writing the associated embedded software. We are happy that our team now covers almost all those areas of expertise; we are currently selecting an embedded software engineer who will complete the broad range of technical profiles needed to develop reliable satellite components.

The second challenge is making SARA reliable. The reason why this type of component is not widely used on board small satellites is that people don’t want moving parts, as they’re afraid they will break, so they want to keep the complexity down. Complexity also drives the price up. What we are trying to do is make mechanisms and moving parts become more standard, even for small satellites, and we want to prove that this is possible through SARA. The point we want to make is that it’s possible to develop something reliable and cheap enough for broad usage on small satellites to improve their performance. We’re doing this on the one side through testing, so that’s a key aspect of this challenge because there will be issues (there always are).

We make mechanisms and moving parts become more standard, even for small satellites

Filippo OGGIONNI

On the other side, we adopted an approach to reliability that you cannot find among competing products – the backup mechanism we developed is key to the goal of being reliable. Indeed, SARA is the only solar array drive assembly on the market that is as reliable as fixed solar panels. Both things matter: sun-tracking solar panels increase the satellite performance, while the backup mechanism makes sure your mission survives in all situations.

What do you look forward to during the ESA BIC programme?

One of the best things about ESA BIC is that it is very well integrated with the Dutch space ecosystem, so we can be around people from both startups and established companies that are very specialised and have been around the industry for a while. We really look forward to getting the most out of our mentor network and in general the companies around us – ESA BIC is the best place for that. The events that ESA BIC organises and the ESA brand are also very useful for us, as well as its proximity to ESA/ESTEC. As an upstream technology developer, this is really important because you have all the experts and cutting-edge facilities at ESTEC, so the support that we might need is just next door. There are a lot of ESA BICs around Europe, but none have this advantage. Also, Revolv was born in the Netherlands and we already knew some stakeholders from the early days of Revolv, so the idea of having our first steps as a company here was a logical choice.

The Revolv team captured hard at work during ActInSpace 2022 hackathon (credit: Studio Crayon Salad)

Anyone actively working on a business idea can take the step to join ESA BIC – and the earlier you get going, the better

FILIPPO OGGIONNI

What have you learned in the first few months as an incubatee?

I think what we are doing well is getting the most out of our connections. The meetings with our coaches and mentors – Johan Leijtens from Lens R&D and Martin Haselhoff from KPN – are very fruitful. Johan went through the journey of developing a high-reliability spacecraft component, so he experienced a similar process as the one we are in right now. In the end, you can take many different paths, but if you have someone who can tell you what the pitfalls are and can pin-point the challenges early on, it can speed up your development. For this reason, Johan is a really good match for us. With Martin, we are working on the business side and he’s helping us refine the estimates of the market we can target in the next few years. Martin already helped other space companies on this topic, therefore he has the experience that we can really benefit from. I would also like to mention Joeri Achterberg and Tim Bloemhof from Scherpe Tanden – the subsidy consultants (and SBIC community partner) – who are supporting us on grant research and application activities. They are super fun to work with and they really know the environment they move within, providing us with advice for establishing a roadmap for our financing path. You can see how four people from the ESA BIC network (mentors and partners) already cover a broad range of topics that we need to work on: technical development, business development and financing.

How would you encourage entrepreneurs to join ESA BIC?

Anyone actively working on a business idea can take the step to join ESA BIC. The earlier you get going, the better. Once you have an idea and a rough plan on how to execute it, then you are ready for incubation – you can figure out everything else during the programme. Being within this ESA BIC ecosystem, you will find the answers quicker by working with your mentors and discussing with other startups. I would say, don’t wait.

After 5 years of engineering education, in aerospace and then in space more specifically, I always thought that I had learned a lot and that most of the learning was done. I was wrong. Revolv taught me that you never stop learning (and you should never stop). After starting Revolv as a company, there was this whole other layer of knowledge and expertise regarding the commercial and financial side of things that we needed to figure out. We were not alone, as we always strived to bring experienced people next to us, ask them questions and show them we are eager to learn. ESA BIC can fast-track this process and make it easier for you as an entrepreneur. There is always something you can learn from other people – maybe it’s not your top priority at the very moment, but it will always come handy at some point. I think this is true for all startups. If you are new to the industry and you don’t have previous connections, ESA BIC Noordwijk is the place you want to be to start this process.

So, any budding space business entrepreneurs who are reading this, listen up! We have our next ESA BIC deadline approaching, so now is the time to start preparing your business plan. We recommend joining the next webinar on 28 March to get tips on preparing your application: details here.

ABOUT REVOLV SPACE

Space assets and services are not fully monetised. Commercial payloads on board small satellites, like cameras, sensors and antennas, operate for a small fraction of the time they spend in orbit due to limitations in small satellite buses. Revolv Space solves these limitations by developing the next generation of critical components, enabling continuous payload operations and full monetisation of space assets. Initially, it tackles the power limitations of small satellites by equipping them with a fail-safe and autonomous Solar Array Drive Assembly. The company is incubated at ESA BIC Noordwijk and is based in Netherlands, with a subsidiary in Turin, Italy. revolvspace.com

Prepare your space business idea for lift-off!

Don’t miss out on the support that can lift off your space business. Take action in 2023. Get ready for the ESA BIC spring application round by discussing your idea with our team, joining the Q&A webinars and preparing your business plan.